Technical Specifications

Innovating technology that provides accuracy, simplicity, portability as well as real speed to your metrology-grade applications.

Volumetric Accuracy

0.025 mm

(0.0009 in)

0.025 mm

(0.0009 in)

0.012 mm

(0.0005 in)(1)

Volumetric accuracy

(based on part size)

(based on part size)

0.020 mm + 0.040 mm/m

(0.0008 in + 0.0005 in/ft)

0.020 mm + 0.040 mm/m

(0.0008 in + 0.0005 in/ft)

0.020 mm + 0.015 mm/m

(0.0008 in + 0.00018 in/ft)(2)

0.020 mm + 0.015 mm/m

(0.0008 in + 0.00018 in/ft)(1)(2)

Form error (Sphere)

N/A

0.030 mm

(0.0012 in)

Form error (Flat)

N/A

0.050 mm

(0.0020 in)

Acceptance test

Based on VDI/VDE 2634 part 3(3)

Based on VDI/VDE 2634 part 3

& ISO 10360(3)

Measurement capabilities (at a working distance of 0.3 m (1 ft))

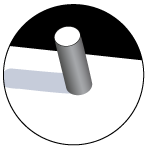

Pin

Pin0.750 mm

(0.0295 in)

0.750 mm

(0.0295 in)

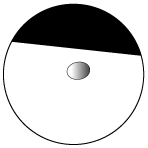

Hole

Hole1.250 mm

(0.0492 in)

1.250 mm

(0.0492 in)

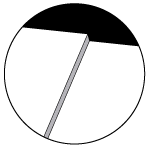

Step

Step0.025 mm

(0.0009 in)

0.025 mm

(0.0009 in)

Wall

Wall0.500 mm

(0.0197 in)

0.500 mm

(0.0197 in)

Measurement resolution

0.025 mm

(0.0009 in)

0.025 mm

(0.0009 in)

Mesh resolution

0.100 mm

(0.0039 in)

0.100 mm

(0.0039 in)

Measurement rate

1,300,000 measurements/s

1,800,000 measurements/s

22 blue laser lines(4)

(+ 1 extra line)

30 blue laser lines(4)

(+ 1 extra line)

Working Distance

200 to 450 mm

(7.9 x 17.7 in)

200 to 750 mm

(7.9 x 29.5 in)

Depth of field

250 mm

(9.8 in)

550 mm

(21.7 in)

Part size range (recommended)

0.05-4 m

(0.15-13.1 ft)

0.05-4 m

(0.15-13.1 ft)

Software

VXelements

VXelements

Output formats

.dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr, .3mf

.dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr, .3mf

Compatible software

3D Systems (Geomagic® Solutions), InnovMetric Software (PolyWorks), Metrologic Group (Metrolog X4), New River Kinematics (Spatial Analyzer), Verisurf, Dassault Systèmes (CATIA V5, SOLIDWORKS), PTC (Creo), Siemens (NX, Solid Edge), Autodesk (Inventor, PowerINSPECT)(5)

3D Systems (Geomagic® Solutions), InnovMetric Software (PolyWorks), Metrologic Group (Metrolog X4), New River Kinematics (Spatial Analyzer), Verisurf, Dassault Systèmes (CATIA V5, SOLIDWORKS), PTC (Creo), Siemens (NX, Solid Edge), Autodesk (Inventor, PowerINSPECT)(5)

Weight

0.94 kg

(2.1 lb)

0.94 kg

(2.1 lb)

Dimensions

(LxWxH)

(LxWxH)

79 x 142 x 288 mm

(3.1 x 5.6 x 11.3 in)

79 x 142 x 288 mm

(3.1 x 5.6 x 11.3 in)

Connection standard

1 X USB 3.0

1 X USB 3.0

Operating temperature range

5-40 °C

(41-104 °F)

5-40 °C

(41-104 °F)

Operating humidity range

(non-condensing)

(non-condensing)

10-90%

10-90%

Certifications

EC Compliance (Electromagnetic Compatibility Directive, Low Voltage Directive), compatible with rechargeable batteries (when applicable), IP50, WEEE

EC Compliance (Electromagnetic Compatibility Directive, Low Voltage Directive), compatible with rechargeable batteries (when applicable), IP50, WEEE

Patents

CA 2,600,926, US 7,912,673, CA 2,656,163, EP (FR, UK, DE) 1,877,726, AU 2006222458, US 8,032,327, JP 4,871,352, US 8,140,295, EP (FR, UK, DE) 2,278,271, EP (FR, UK, DE) 2,230,482,

IN 266,573, EP (FR, UK, DE) 3,102,908, US 10,271,039, JP 6,596,433, CA 2,938,104,

KR 10-2424135

CA 2,600,926, US 7,912,673, CA 2,656,163, EP (FR, UK, DE) 1,877,726, AU 2006222458, US 8,032,327, JP 4,871,352, US 8,140,295, EP (FR, UK, DE) 2,278,271, EP (FR, UK, DE) 2,230,482,

IN 266,573, EP (FR, UK, DE) 3,102,908, US 10,271,039, JP 6,596,433, CA 2,938,104,

KR 10-2424135

(1) Performance obtained with Limited Edition. Limited Edition is able to deliver improved accuracy through optimized manufacturing and calibration processes.

(2) Performance obtained with scale bars included in the Accu+ Kit.

(3) Performance tests done in Creaform's ISO/IEC 17025 accredited calibration laboratories.

(4) Laser class: 2M (eye safe).

(5) Also compatible with all major metrology, CAD, and computer graphic software through mesh and point cloud import.

International Support, Repair, and Calibration 3D Metrology Centers

Our Centers are located all around the world and offer the following services* in different languages.

Ask our experts

Software and hardware Technical Support Helpline

3D scanner basic and advanced repair

Equipment maintenance and tuning

Loaner services

3D scanner component replacement

Parts reselling

Warranty renewal

* Services may vary depending on 3D metrology centers.

Rigorous Manufacturing 3D Scanner Process

Creaform designs, manufactures, and calibrates HandySCAN 3D scanners with the highest quality management system according to internationally recognized standards ISO 9001 and ISO 17025.

HandySCAN BLACK’s acceptance test is based on VDI\VDE 2634 which is ISO 17025 accredited to guarantee traceability to international standards.

Each scanner is delivered with a personalized certification and fully documented test results.

International Metrology High-Quality Standards

At Creaform, product and service quality is our top priority. Being pioneers in portable 3D measurement, we are committed to exceeding our customer requirements by developing innovative solutions. We are invested in continuously improving processes, setting new standards for the industry and ensuring full satisfaction of our clientele.

HandySCAN BLACK’s acceptance test is based on VDI\VDE 2634 which is ISO 17025 accredited to guarantee traceability to international standards.

Each scanner is delivered with a personalized certification and fully documented test results.

International Metrology High-Quality Standards

At Creaform, product and service quality is our top priority. Being pioneers in portable 3D measurement, we are committed to exceeding our customer requirements by developing innovative solutions. We are invested in continuously improving processes, setting new standards for the industry and ensuring full satisfaction of our clientele.

Interested in the HandySCAN 3D|BLACK Series scanners?

Contact our Creaform experts. They’ll find the right solution adapted to your needs!